China has announced a new “lunar brick-making” system designed to make building blocks directly from lunar soil, a capability that — if it works as advertised — will take lunar base construction from concept art to field engineering. State media reports say the device has already made bricks on Earth using lunar soil simulant and is ready for in-orbit exposure testing ahead of a potential trial on the moon under the Chang’e-8 mission planned for 2028. Published sources such as Xinhua and other international outlets have outlined the research and upcoming tests.

What China says it has built

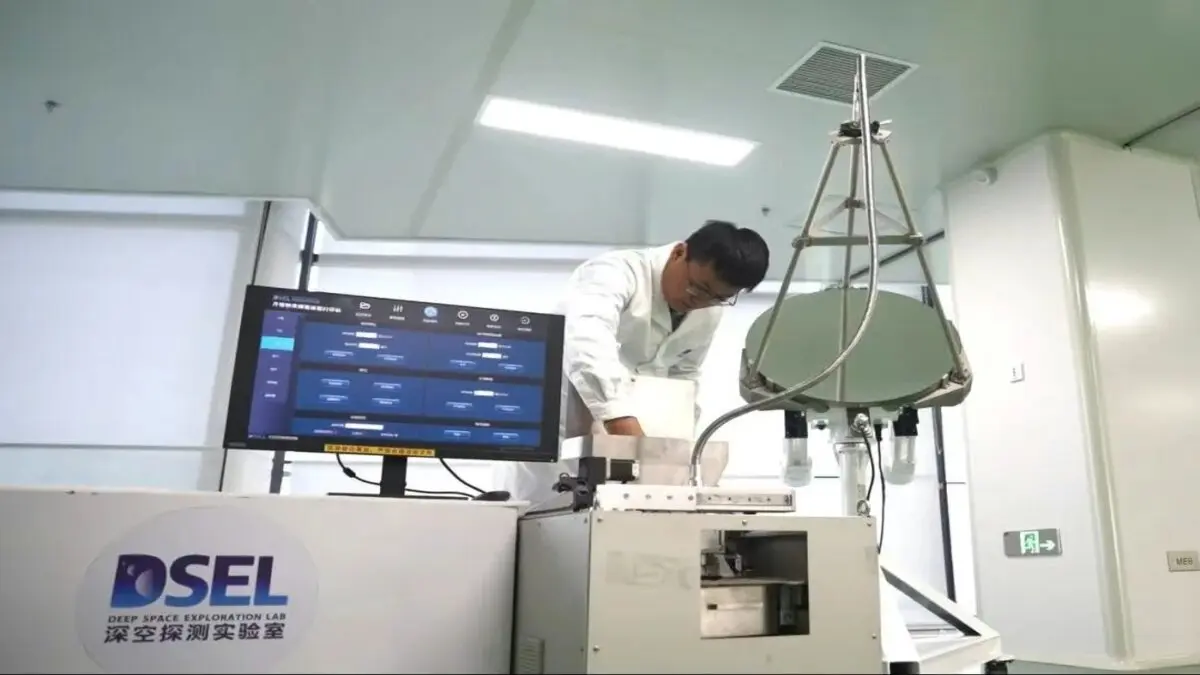

Xinhua reported that a Chinese research team has developed a machine capable of making “lunar bricks” from regolith, with the goal of enabling “building houses on the moon with local materials.” The announcement did not reveal full technical drawings but emphasized in-situ resource utilization (ISRU) to reduce launch mass from Earth.

Wu Weiren, chief designer of Beijing’s lunar program, described it as “the world’s first device to make bricks from lunar soil,” and explained that the system focuses sunlight to melt and fuse the dust at temperatures of about 1,400-1,500 °C. This solar-sintering approach avoids bringing in large quantities of binder from Earth, aligning with ISRU objectives.

- (XHNews/X)

From the lab to orbit—and then to the moon

China has already made bricks from lunar regolith simulant and plans to expose them to vacuum, thermal cycling, and radiation on the Tiangong space station to assess durability before attempting production on the surface. These exposure experiments are currently being conducted and the samples are scheduled to return to Earth for analysis.

If successful, Chang’e-8 — currently scheduled for around 2028 — will attempt an ISRU demonstration at the moon’s south pole, which China aims to assemble in the 2030s. Mission overviews consistently list on-site 3D printing and materials processing as primary objectives.

Why it matters: Engineering and strategy

Mass, money, and risk. Launching structural materials remains a major logistical hurdle. Turning regolith into load-bearing blocks on-site can remove tens of tons from the payload manifest, reducing cost and complexity. Solar sintering scales effectively—mirrors and fiber-fed concentrators pack tightly but deliver high energy density where it counts.

Thermal and mechanical realities. After fusion, the bricks have to withstand -170°C to +120°C swings, micrometeoroid impacts, abrasive dust, and maintain tolerance for pressurized environments. That makes an orbital contact mission a viable gateway for many years before any preparations for a lunar lander are announced.

Dust is the enemy. Lunar dust is highly abrasive and electrostatically sticky. High-temperature processes risk vaporizing thin materials around optics and joints, degrading performance. While dust-tolerant mechanisms and enclosures may already be in the design, only long-term surface operations will confirm capability.

Geopolitical cue. Demonstrating a raw ISRU before a raw landing is a strategic maneuver. It supports China’s goal of a first raw lunar landing around 2030 and solidifies the ILRS offering as a cost-sharing, capability-rich option. On-orbit tests and the Chang’e-8 timeline reinforce that narrative.

What’s New—and What’s Not

Proposals for lunar “lunar bricks” are not new. What is clear now is this: Simulant bricks have already been built, in-orbit exposure tests are underway, and a named lunar demonstration mission with a clear timeline is underway. This is the most tangible path from concept to lunar construction.

Potential Upsides—and Things to Watch For

Upsides

- Lower logistics costs: Less payload mass dedicated to the structure means more capacity for science, life-support, and protection.

- Radiation shielding: Regolith-based bricks offer passive protection options equivalent to imported materials.

- Industrial learning curve: Mastering manufacturing in lunar-like conditions offers crossover benefits—such as oxygen extraction, metal purification, and dust management.

Things to consider

- Material brittleness: Rapid cooling in a vacuum can create microcracks; processes such as annealing or layered fabrication may be necessary.

- Optics fouling and maintenance: Solar concentrators require protection or cleaning methods—challenging in lunar dust.

- Human-rating gap: The move from unpressurized berms to pressurized shelters requires hybrid solutions that combine regolith coverage with inflatable modules.

Highlights

China’s “lunar brick” program is moving from theory to practice. With orbital exposure tests underway and the Chang’e-8 mission clearly in the pipeline, Beijing ISRU is bridging the gap between concept and construction in space. While not an immediate path to pressurized habitats, the development marks the first supply chain beyond Earth—from lunar dust to potential structures. Such progress invites a broader reassessment among Artemis partners and others: what can be made, how quickly, and at what cost.

“We have now developed the world’s first device that produces bricks made from lunar soil,” said Wu Weiren, chief designer of China’s lunar exploration program, describing the solar-powered regolith-fusion system China aims to test on Chang’e-8.”

Continue Reading: Cambodia and Thailand Agree to ASEAN Ceasefire Monitors as Border Tensions Ease

FAQs

China’s lunar brick project is a new system that makes building blocks directly from lunar soil, also known as regolith. Instead of sending heavy construction materials from Earth, this machine uses sunlight to heat lunar dust to very high temperatures and fuse it into solid bricks. These bricks could be used to build shelters and bases on the Moon in the future.

The biggest challenge in building on the Moon is cost and transportation. Transporting tons of construction materials from Earth is very expensive. By making bricks on the Moon itself, China can save money, reduce payload weight, and build stronger local structures. These regolith bricks can also provide protection against radiation, extreme temperatures, and micrometeoroids.

China plans to test brick technology on the moon on the Chang’e-8 mission, which is expected around 2028. Before that, they are testing bricks made on Earth in space to see how they handle radiation, vacuum, and temperature changes. If these tests work, the lunar mission will demonstrate brick-making on the lunar surface for the first time.

This project is about more than just science — it’s also about strategy. China’s progress in using lunar soil for construction puts it ahead in a new space race, especially in terms of building a long-term lunar base. The “lunar brick” success could also push other programs like NASA’s Artemis mission to accelerate their own research into in-situ resource utilization and lunar construction.

Leave a Reply